Company name: Linyi Zhouxing Building Materials Co., Ltd.

Sales Manager:Ada Yan

Phone:0086-13793941918

Director: Mr zhou

Phone:0086-13791556681

Tel: 0086-539-7952337

Company address: Luozhuang high tech Development Zone, Linyi, Shandong

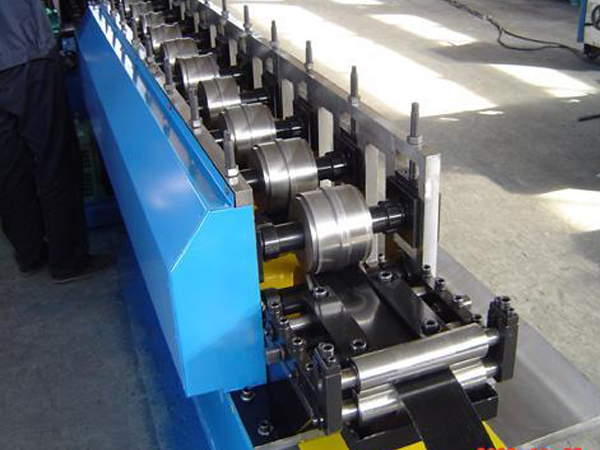

The daily maintenance of the keel processing equipment is not much less

Keel mechanical inspection of parts of the hidden defects, such as aging, fine lines and so on. Check the strength and elasticity of the part of a keel

Check the roughness of the mechanical surface of the keel, the degree of damage and so on. Check the geometric accuracy of the parts. Check the quality of the parts of the keel

The regular maintenance of the keel processing equipment is very important, and its daily inspection is also very necessary.

For long-term working state of the keel machine, it must be lubricated, this step is an indispensable step for each machine and other equipment. According to the period of lubrication, keel machine can be divided into non intermittent lubrication and continuous lubrication. It is believed that the keel processing equipment can guarantee the work effectively and ensure the long service life. Then according to the working efficiency state, cycle, daily maintenance rules of the keel machine, the lubrication period of the keel machine is determined. For the normal operation of keel machine under the condition of general requirements is best not more than twenty lubrication cycle to thirty days, to ensure the lubrication cycle in five to twenty days, do not hold too long, also need to pay attention, for the keel machine under operating condition, be sure to check the good and its accessories as part of the overall, therefore, should be in place lubrication keel processing equipment, and the daily work of the maintenance is priority among priorities, a cold roll forming machine is good to require different aspects of maintaining and nurturing to ensure its service life longer.