Company name: Linyi Zhouxing Building Materials Co., Ltd.

Sales Manager:Ada Yan

Phone:0086-13793941918

Director: Mr zhou

Phone:0086-13791556681

Tel: 0086-539-7952337

Company address: Luozhuang high tech Development Zone, Linyi, Shandong

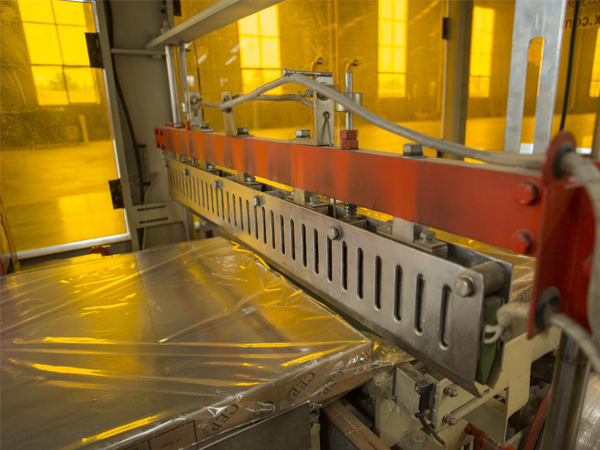

Maintenance method of full automatic packaging machine

Always check for automatic packaging machine vacuum filtration, oil mist, triple 24 to ensure that oil mist, oil cup oil (sewing machine oil filter bowl), anhydrous.

Incline placement and impact are not allowed during the handling, and the handling is not allowed.

The full automatic packing machine must have reliable grounding device when it is installed. It is strictly forbidden to put the hand under the heating rod to prevent the injury and cut off the power immediately in the case of emergency.

When the first ventilation power outage, firstly cut off gas.

The heating strip and silica gel strip should be kept clean, and the foreign objects should not be sticky, so as to avoid the sealing quality.

On the heating rod, the two layers of paste under the heating plate are insulated, and should be replaced in time when they are damaged, so as to avoid short circuiting.

Continuous work for 2-3 months, we should open the rear cover 30, slide the location and switch bump and add lubricating oil. The connection points on the heating rod should be lubricated according to the usage.

The automatic packaging machine should be used in the environment where the temperature is between -10 and 50 degrees, the relative humidity is not more than 85%, and there is no corrosive gas in the surrounding air and no dust and explosion hazard. Like a packer and a shrink machine, this packing machine